Straw bale

Key points

- Straw bales were first used for building soon after the invention of baling machines over a century ago.

- With straw bale construction, bales are usually attached to a frame and laid like giant bricks. Bales are compressed to minimise settlement and movement.

- The bales must have a moisture content of less than 15% and ideally less than 10%.

- Straw bale walls need render to protect them from rain, fire and pests.

- Straw bales themselves have very low thermal mass, but the render usually provides reasonable thermal mass.

- Straw bales are among the most cost-effective thermal insulation available.

- Once rendered, straw bales have very low fire and pest risk. Even if a fire does reach the bale itself, the compression of the bale minimises oxygen availability and thus fire risk.

- Construction is labour intensive but relatively simple, and lends itself to owner–builder or volunteer work.

Understanding straw bale

Straw has been used as a building material for centuries for thatch roofing and also mixed with earth for cob walls, and wattle and daub walls. Straw bales were first used for building over a century ago by settlers in Nebraska in the United States, shortly after the invention of baling machines.

Straw is the springy tubular stalk of grasses such as wheat and rice that are high in tensile strength. It is not hay, which is used for feeding livestock and includes the grain head. Straw is composed of cellulose, hemicellulose, lignins, and silica. It breaks down in soil, so waste straw can be used as mulch. Different grasses have slightly different qualities: rice straw, for example, has a significant amount of silica which adds density and resists decomposition.

Straw bale walls are rendered and are surprisingly resistant to fire, pests and decay. The Australian straw bales suitable for domestic construction have 2 strings (American how-to books often show 3-string bales) and are typically 900mm long × 450mm wide × 350 to 400mm high, and weigh 16 to 20kg. Agribusiness produces large round straw bales that cannot be used for building purposes but rectangular ‘jumbo bales’ are available (2400mm × 1200mm × 1200mm) which can be used for large structures and require mechanical lifting.

Photo: © Simone Cottrell

Buildability, availability and cost

Straw bale construction rates highly for buildability because it can be very straightforward and is well suited to workshop and volunteer-based building programs. Many volunteer and workshop-based bale raisings happen around Australia. The very active and informed network of straw balers constantly explores ways to improve and quantify bale building technology. In 2002, the nonprofit association Ausbale was formed to develop and provide information on straw bale building techniques, and performance.

The general availability of straw bales is good with many settled parts of Australia being within an hour or so of wheat or rice straw supplies. Straw bale is a low-cost material but requires labour-intensive construction techniques. Projects that incorporate some volunteer or workshop-based construction can deliver cost savings. A large detached dwelling with a high standard of fittings and finishes, and built through conventional building contractual arrangements, costs about the same as if it were in double brick, but with a better cost saving through thermal performance.

Appearance

Finished straw bale walls are rendered with earth and cement so that the straw is not visible. The final appearance of rendered straw bale can be very smooth and almost indistinguishable from rendered masonry, or it can be more expressive and textural.

Photo: © Simone Cottrell

Structural capability

The structural capability of straw bales is surprisingly good. In the loadbearing (‘Nebraska’ style) straw bale method, walls of up to 3 storeys have been constructed. Most straw bale construction uses a frame of timber or steel for the building structure to comply with the National Construction Code. There are many examples of multistorey buildings in framed straw bale construction.

Durability and moisture resistance

Provided the straw is protected and not allowed to get waterlogged, straw bale buildings can have a lifetime of 100 years or more. The survival of historic straw bale structures in Nebraska and Alabama demonstrates their durability in climates with variable moisture and temperature.

The factor that will most affect straw bale wall durability is long-term or repeated exposure to water. If the moisture content is above 20% by weight, the fungi in bales produce enzymes that break down straw cellulose after 2 or 3 weeks. The best way to prevent rot in a finished structure is to create a waterproof, breathable wall.

Rice straw can make more durable bales than wheat straw because its high silica content improves rot resistance. Rice straw bales are slightly denser, and therefore heavier, but can otherwise be treated the same as straw bales.

Photo: Paul Downton

Thermal mass and insulation

Straw bales themselves have very low thermal mass, being composed, by volume, mostly of air. However, the cement and earth renders typically used on straw bales result in finished walls having appreciable thermal mass in the masonry ‘skins’ either side of the insulated straw core. With earthen renders, a thick render skin of up to 75mm can be achieved, providing significant thermal mass.

Straw bales have excellent insulation properties – among the most cost-effective thermal insulation available. A typical straw bale wall has an R value greater than 7. Straw has a similar insulation value to fibreglass batts for the equivalent thickness and is much cheaper.

The design goal in any structure must be to complement the insulation performance with the performance of the rest of the building. Thus, it is essential to insulate roofs and windows to maintain the overall performance of a straw bale building.

Sound insulation

Straw bales provide cost-effective sound insulation, which contributes to the liveability of this kind of construction. Walking into the space created by a straw bale structure, you can appreciate the quietness and hear the difference from conventional buildings.

Fire and pest resistance

Straw bales are tightly packed and covered with a skin of render. Fire cannot burn without oxygen, and the dense walls provide a nearly airless environment, so the fire resistance of compacted straw is very good. Testing by the CSIRO on behalf of Ausbale and the South Australian fire authority in 2002 on 3 kinds of standard size rendered straw bales (earth; lime and sand; lime, sand and cement) produced a 2-hour fire rating. Samples were subjected to a simulated bushfire front with a maximum heat intensity of 29kW per square metre without igniting the sample wall sections.

The potential for fire to take hold can also be minimised. Try to cap walls by continuing render over the top of the bales and plates so that an inadvertent flue effect does not support combustion by bringing in air to fuel the fire. Always seek local regulatory advice if the building is sited within a bushfire-prone area.

Maintain vigilance during construction and ensure that loose straw and sawdust or other combustibles are not left in or around the structure at any time. Some trades use fire, such as oxy cutters and welders. Take special care to manage activities that are of high fire risk.

A completed wall has excellent resistance to pests, and the normal termite protection measures required in the National Construction Code are generally sufficient. Most straw bale construction is coated with plaster or render which is adequate to keep animals out, and if they do manage to get inside, densely packed straw makes it hard for them to navigate through the space. However, prevent infestation of mice during construction when the bales are relatively unprotected. During construction, consider using traps and baits to ensure the finished structure is sound and pest-free.

Photo: Paul Downton

Toxicity and breathability

The natural materials of straw bale construction are safe and biodegradable. Some people are allergic to the dust created during straw bale building. No toxic fumes are released when straw burns and there is no toxic end to the straw bale construction cycle. Straw bale walls have good breathability, allowing air to slowly permeate the structure without moisture penetration. Earthen, and some earth-lime renders, may allow walls to ‘breathe’ better than cement render, especially renders that have a high cement-to-sand ratio.

Environmental impacts

Straw is derived from grasses and is a renewable building material. Straw is a waste product; unlike hay, it cannot be used for feed, and much of it is burned at the end of the season. Using straw for building reduces air pollution and stores carbon. The straw left over from building can be used as mulch on gardens.

Straw bales contain a high level of renewable material. Straw has a 6-month growing cycle and is biodegradable. To be sustainable in the long term, straw should be grown in a way that maintains the soil quality. Fertilisers and pesticides associated with industrial farming practices increase the environmental impact of straw bales, as does the use of baling twine made from petroleum products.

Straw bales are inherently low in embodied energy, but most are produced by fossil-fuelled machinery, tied together by plastic twine and transported long distances – increasing their embodied energy. Straw bale walls often require concrete footings that add further to the energy cost of their construction.

Rice straw is a by-product of irrigation agriculture that changes the flow and water balance of catchments in Australia’s major river systems. Wheat straw is less water-intensive.

Greenhouse gas emissions associated with straw bales are very low. One tonne of concrete requires more than 50 times the amount of energy in its manufacture than straw. Using straw for building stores carbon that would otherwise be released, however the amount sequestered per dwelling is relatively small.

Straw’s primary value is as an insulating material that enables houses to use less energy and have lower greenhouse gas emissions over the building’s life.

Photo: © Simone Cottrell

Using straw bale

Design and detailing

Loadbearing walls

The earliest straw bale buildings of over a century ago were loadbearing. Australian straw bale experts recommend a maximum wall height of 2.5m when using standard-sized bales. Bales for loadbearing construction should ideally have tighter strings than normal.

Loadbearing straw bale construction uses relatively simple techniques that are forgiving to novice builders and yet have sufficient flexibility to allow the creation of design features such as curved walls. Its limitations are that openings for windows and doors should not exceed 50% of any given wall surface area and the maximum unbraced wall length is about 6m.

Photo: Paul Downton

Bales should be laid like bricks in a ‘running bond’ (that is, butted end to end with joints that fall in the middle of the bale on the rows above and below). Corners should allow for at least a full bale return in each direction to give strength and stability.

After the walls are laid, they have to be precompressed before taking any structural loads. Of the variety of methods for achieving this, the most popular and practical method is grippling.

Grippling runs 2.5mm high-tensile fencing wire vertically around the bale walls every 450mm. The wires are run through a bottom ‘plate’ (generally a ladder-frame timber structure secured to the footings) and over a top plate (similar to, or as simple as, a plank of wood). Gripples are proprietary soft metal clamps that hold the wires in tension. They were invented for fencing use and are available with the associated specialist tools through fencing suppliers.

Photo: Paul Downton

Early experiments in bale building used excessive vertical reinforcement to tie bales to footings and to each other. Good results with better economy in materials can be achieved without reinforced steel bars, and the vertical spiking of bales is largely unnecessary with the wire and grippling method.

Like giant bricks, straw bales need to be cut to fit into wall lengths. The fewer cuts the better. Design walls in straw bale length modules and calculate heights from working out straw bale dimensions and allowing for compression of 50 to 75mm per single-storey height of bales.

Slicing a bale requires that it is first ‘sewn’ at the desired finished length; the original twine is then cut. The idea is to produce 2 short bales with the same compression as the original, held by new sets of twine. The cutting and trimming of bales can be done with hand tools or, more commonly, a chainsaw with a blade length of at least 400mm.

Photo: Paul Downton

Openings

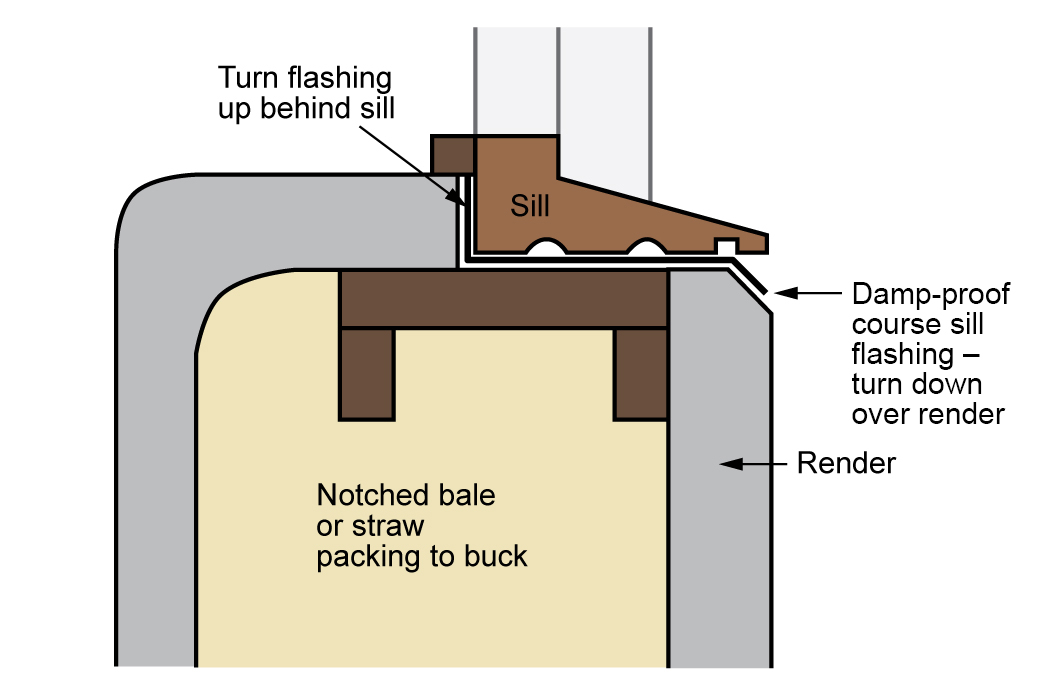

Windows, doors, and other openings in straw bale walls generally have to be placed within a frame designed to withstand compression loads, unless the window or door frames are themselves strong enough to do the job. These frames are sometimes called ‘bucks’. With bucks to resist distortion, almost any kind of window or door can be set into a straw wall, either ‘floating’ in the bales, or tied to frames. Until the walls have undergone final compression, window and door frames, and bucks must have adequate temporary cross-bracing.

Source: Paul Downton

It is best to set any frames with their faces flush to the outside face of a wall to improve weather protection. This also makes a deeper ‘reveal’ to the interior, opening up possibilities for deep interior sills, window seats, and angled or sculpted surrounds to the openings that can improve overall daytime lighting qualities. Niches can be cut into straw bale walls in almost any position or formation provided care is taken not to cut into the twine that binds the bales together.

Use standard flashing materials and methods to weatherproof window openings that are exposed to direct rainfall.

Source: Paul Downton

Finishes

Straw bale walls need render to protect them from rain, fire, and pests. Wall claddings such as corrugated steel sheets cannot provide sufficient protection because they do not seal the surface of the bales. Renders should avoid creating a nonbreathable skin that prevents the movement of air because this may encourage mould, fungus, and decomposition of the straw.

Before any render is applied, the walls must achieve final compression, and licensed tradespeople must install electrical and plumbing conduits. Details of these installations depend on the design of the building. Avoid placing water pipes adjacent to unrendered bales to minimise potential problems with future leaks.

Australian straw bale construction uses 3 main kinds of render: cement, lime and sand; lime putty and sand; and earthen render (sometimes incorporating lime).

Final finishes on cement renders can range from clear acrylic-based water repellents to traditional coloured lime wash. Cement renders can be finished with a lime putty render topcoat. The 3 layers of render should be progressively weaker to reduce the potential for cracking caused by having too brittle an external layer. Lime putty renders resist cracking and hold coloured oxides well. Earth renders are gaining popularity as concerns about their effectiveness have been addressed. The main advantages of using earth renders are minimising environmental impact, and time spent in preparation and application. Earth renders significantly reduce the embodied energy of the building.

Render can be applied directly to the face of a straw bale wall, particularly earth renders. Cement renders are not recommended as they do not allow for air or moisture to pass through. If cracks occur in cement render, water cannot breathe out if it enters the wall and may cause the straw bales to decay. Lime renders allow the walls to breathe and any excess moisture to leave the straw. This ensures the longevity of the straw bales and therefore the building.

Straw bale builders have moved away from the use of chicken wire in Australia. This method is still used in the United States. There are various ways of improving adhesion and reinforcing the render skins, including the use of fibreglass netting instead of chicken wire. Curved corners, window and door returns, and all junctions between dissimilar materials are best dealt with by having expanded metal mesh as the substrate for any render.

Photo: © Simone Cottrell

All structural design should be prepared by a competent person and may require preparation or checking by a qualified engineer.

Source: Paul Downton

The build process

Construction process

The main aim of the various straw bale construction methods is to achieve good bale compression to minimise settlement and movement. Bales must be well compacted and have a moisture content not exceeding 15% – below 10% is preferable.

While footings are being prepared, work can proceed on other aspects of the building. Making frames and ‘bucks’ in advance of site works can speed up construction.

The vertical and horizontal stability of straw bale walls needs to be secured by tying bales to structural frames or pinning between bales and structural elements. There is growing consensus that the extensive use of reinforced steel bars and excessive pinning that characterised early straw bale construction is not necessary.

Bales are laid like giant bricks and, as with bricks, it is preferable to interlock the bales for a stronger and more stable wall, whether or not it is loadbearing.

Prefabricated straw bale walls are becoming more popular due to the time and cost savings. They range from 255mm to 350mm thick and can be built offsite in a factory before being transported to the building site. Some prefabricated straw walls come pre-rendered and the services already ‘roughed-in’, which reduces waste (in time, transport, materials, and handling).

Some tips for construction are:

- Build test walls before proceeding with the final construction.

- Keep bales dry during storage and construction, and ensure moisture content of straw bales is below 15%

– Cover otherwise unprotected walls with tarpaulins or plastic sheets (which should be kept ready for easy deployment).

– Keep on-site storage times to a minimum.

– If bales do get slightly wet they can often be dried out sufficiently to be usable. Wet bales can be taken out and replaced. If the sides become wet (for example, by driving rain) this should not be a problem as straw does not ‘wick’ water into itself. The natural movement of air or wind around the bales should be sufficient to dry them out without damage. - Try to eliminate pests with the use of traps: straw attracts mice and it is not unusual to find mice in straw bale deliveries.

- Continue render over the tops of walls to minimise the potential for drawing air through the wall in the event of fire (which might allow it to smoulder).

- Pick up and bag all loose straw (for use as mulch) during construction to avoid creating a fire hazard.

Footings

A straw bale wall requires footings with a similar load-carrying capacity to that required for a masonry wall, although a straw wall is generally lighter (1 mud brick weighs about the same as a straw bale). To facilitate compliance with the National Construction Code, footings are usually concrete strips or slabs. The width of a footing under a nominal 500mm rendered straw bale wall is typically 450mm (subject to soil conditions); this results in approximately 2m3 of additional concrete for a 150m2 home, adding a one-off emission of about 300kg of carbon dioxide. For more information refer to Embodied energy.

There have been successful experiments with rubble trench and rubber tyre footings, and several straw bale buildings in Australia are built on piers, bearers and joists. As with mud bricks, the non-loadbearing option means a roof structure can be raised in advance of the walls to provide a protected environment for building works.

Source: Paul Downton

Frames

Although it is possible to build strong and effective single-storey straw bale structures, it is often easier to ensure National Construction Code compliance and predictable engineering outcomes if the walls are constructed as infill elements between loadbearing frames. Non-loadbearing straw bale walls are similar to loadbearing but are generally more complex and have to be connected to the frames they sit in. The frames allow more freedom in the design, and placement of openings and a running bond is not as critical as it is with loadbearing walls. Pre-compression is still necessary to avoid problems with the bales settling over time.

Framework and posts can be constructed off site and can enable a roof to be constructed in advance of the wall raising, providing shelter during the wall construction process. Framed construction provides more design freedom for wall and opening placement.

Photo: © Simone Cottrell

Joints and connections

Straw bale walls can be joined to almost any construction provided attention is paid to flashing details, preferably with the assistance of a competent architect or designer. When one material joins another, accommodate for differential movement and ensure there is no passage for moisture penetration.

The roof timbers or steel members can spring from the columns (particularly in the case of steel) or bear on wall plates. It is recommended that roofs have a considerable overhang to afford some protection to walls from driving rain. In more sheltered areas this requirement is less important, but take care to use a good-quality render and waterproofing finish.

Photo: Paul Downton

Fixings

It is possible to fix substantial loads to loadbearing and non-loadbearing straw bale walls by forming clamps made from planks of timber on either side of the bales, tied through the wall with high-tensile wire and tensioned by grippling or twisting. Other methods for fixing details such as shelves and kitchen cupboards simply use elements connected to the loadbearing frame. With cement-rendered interior skins that are a nominal minimum of 30mm thick, it is possible to hang pictures and other items from plugged holes in the thin masonry skin.

References and additional reading

- Amazon Nails (2001). Information guide to straw bale building: for self-builders and the construction industry. Amazon Nails, Todmorden, United Kingdom.

- Australian Straw Bale Building Association.

- Gray A and Hall A (2000). Strawbale homebuilding. Earth Garden Books, Trentham, Victoria.

- Hodge B (2006). Building your straw bale home: from foundations to the roof. Landlinks Press, Collingwood.

- Hollis M (ed) (2005). Practical straw bale building. Landlinks Press, Collingwood, Victoria.

- House of Bales.

- Lacinski P and Bergeron M (2000). Serious straw bale: a home construction guide for all climates. New Society Publishers, Gabriola Island, Canada.

- Magwood C and Mack P (2000). Straw bale building: how to plan, design and build with straw. New Society, Gabriola Island, Canada.

- Partridge H (2003). Straw bale construction. Environment design guide. PRO 12, Australian Institute of Architects, Melbourne, Victoria (AIA members only).

- Steen A and Steen B (2000). The beauty of straw bale homes. Chelsea Green, White River Junction, Vermont.

Learn more

- Read Passive heating and Passive cooling for tips on designing your home to work well in winter and summer

- Look at Condensation for ideas on how to reduce or eliminate condensation in your home

- Explore Materials for ideas on methods and materials for new home construction

Authors

Original author: Paul Downton 2013

Updated: Department of Industry, Science, Energy and Resources 2020